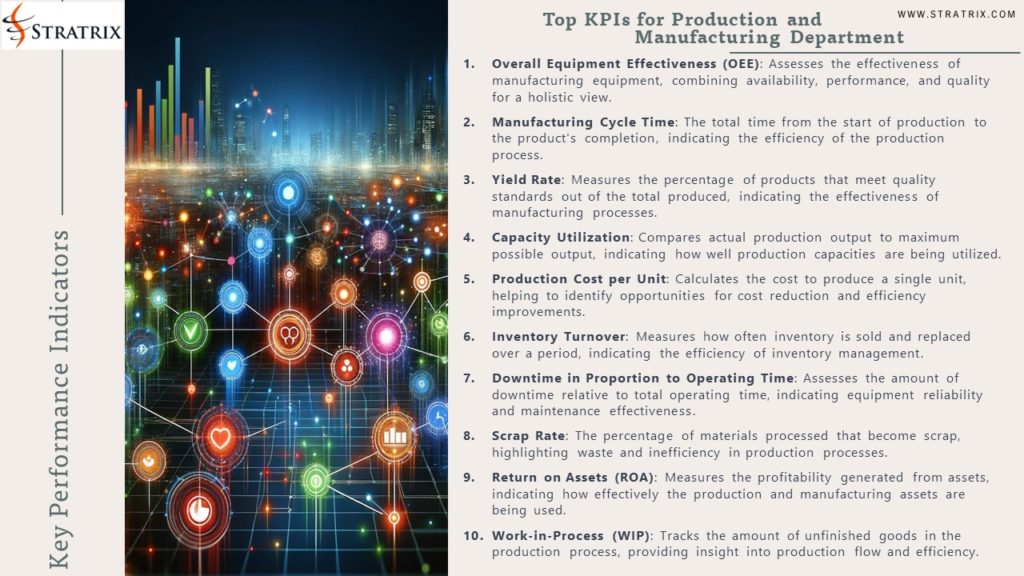

Top KPIs for Production and Manufacturing Department

1.Overall Equipment Effectiveness (OEE): Assesses the effectiveness of manufacturing equipment, combining availability, performance, and quality for a holistic view.

2.Manufacturing Cycle Time: The total time from the start of production to the product’s completion, indicating the efficiency of the production process.

3.Yield Rate: Measures the percentage of products that meet quality standards out of the total produced, indicating the effectiveness of manufacturing processes.

4.Capacity Utilization: Compares actual production output to maximum possible output, indicating how well production capacities are being utilized.

5.Production Cost per Unit: Calculates the cost to produce a single unit, helping to identify opportunities for cost reduction and efficiency improvements.

6.Inventory Turnover: Measures how often inventory is sold and replaced over a period, indicating the efficiency of inventory management.

7.Downtime in Proportion to Operating Time: Assesses the amount of downtime relative to total operating time, indicating equipment reliability and maintenance effectiveness.

8.Scrap Rate: The percentage of materials processed that become scrap, highlighting waste and inefficiency in production processes.

9.Return on Assets (ROA): Measures the profitability generated from assets, indicating how effectively the production and manufacturing assets are being used.

10.Work-in-Process (WIP): Tracks the amount of unfinished goods in the production process, providing insight into production flow and efficiency.